Today we’re going to pull back the curtain and reveal the inner workings of the well-known welding methods TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), both of which are used at the MILOS factory.

Which method is better? Neither one! Both produce strong, high quality welds. The main difference between them is how the joints are fused. In the end, the method you choose depends on the type of metal you’re welding, the weld you require, and your environment.

Let’s take a quick look at each one.

TIG

The TIG welding method creates attractive welds that do not require any finishing process.

.png.aspx)

It’s most suitable for welding thinner metal, where precise welds are required, such as aluminium truss tubes.

The TIG method makes use of a non-consumable tungsten electrode to run a current through the metals being joined. A filler metal may, or may not, be used and argon gas, or other inert gases like helium, is required during the welding process to protect the weld from contamination. In cases when a filler material is not used, the pieces of metal being welded must get hot enough to form a bond with each other.

Compared to MIG welding, TIG is a slower process and demands a higher degree of welding skill. If a filler is used, increased hand coordination is required, as one hand must hold the torch at the correct angle, while the other hand feeds the wire to create a uniform puddle used to fuse the metals together.

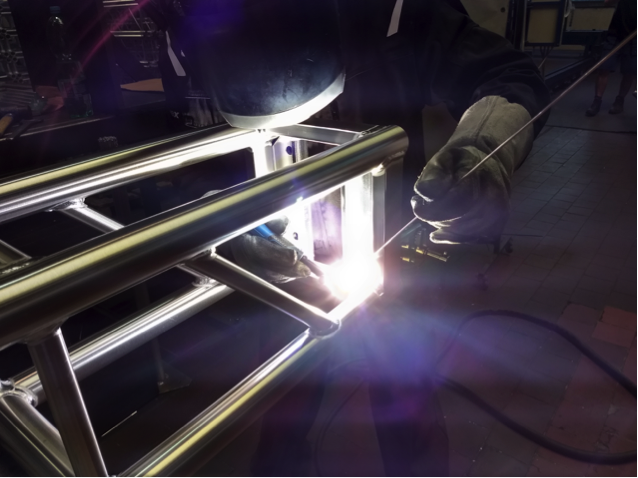

MIG

The MIG welding method is more suited for thicker metals and where longer weld lines are required. It can be used on stainless steel, mild steel and aluminium.

Welding is carried out with a consumable spool of metal wire that is fed by the MIG welding machine to the metal joint area through a contact tip in the MIG “gun”. When the “trigger” of the gun is pulled, its contact tip is electrically charged, which heats the tip and melts the wire to create a weld puddle. Before the puddle is created, argon gas is released from the gun to form a gas shield around the area where the weld puddle will be produced to protect against contamination. Once the puddle is formed, it’s then used as a filler to fuse the two pieces of metal together.

Contrary to TIG welding, MIG only requires one hand to perform the welding operation, thereby making it a faster and easier method.

TIG and MIG at MILOS

The TIG method is used during the production of MILOS aluminium truss and is carried out both manually and by machine in the MILOS factory. For the automated TIG welding, a CNC machine attaches end connectors to MILOS aluminium truss sections. This allows for a very smooth finish and consistent attachment across the truss ends.

MIG welding is used mainly for production of the MILOS Steel Truss line. MILOS has heavily invested in its steel welding process and devoted more than a year for the training and certification of its steel truss welders.

Although the above information has been summarized to give you a quick overview of these two welding methods, we hope it has still armed you with enough information to be a kowledgeable participant in future welding conversations.